The static pressure automatic molding line is a new casting process that fills the cavities in the mold by injecting molten metal into the mold and applying high pressure. Compared with traditional casting processes, static pressure molding lines have higher production efficiency, better casting quality and less energy consumption. They are widely used in automobile manufacturing, construction, electric power, aerospace and other fields.

The static pressure automatic molding line is an advanced new type of automobile wheel hub production and forging equipment. It adopts a PLC control system and has high precision and efficiency.

The static pressure automatic molding line consists of a sand processing system, a static pressure molding host, a molding auxiliary machine, a pouring cooling system, a shakeout system, a conveying system and a central control system.

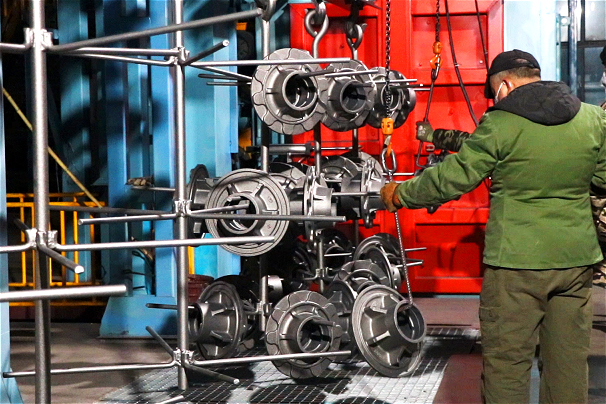

Advanced production technology realizes automated production, improves production efficiency and ensures product quality. At the same time, high-quality raw materials are used to make product quality more reliable.

The series synchronous control system of low energy consumption realizes the power control and adjustment of the production line. At the same time, the air suction inlet of the production line is also equipped with an adjustable speed motor, and the air inlet volume can be automatically adjusted, resulting in significant energy saving effects.

The fully automated production process enables intelligent control and monitoring of the production process. At the same time, it also has functions such as automatic feeding, automatic waste discharge, and automatic edge alignment, making the production process more convenient and faster, and improving production efficiency and quality.

The size deviation of the casting is small, and the size accuracy reaches CT7~CT8, which is higher than the accuracy of traditional pneumatic microseismic high-pressure molding.

Customized design according to the actual needs of customers.

The stable characteristics of the static pressure molding process can produce castings with high repeatability and high dimensional accuracy. It is especially suitable for the production of large-volume castings and reduces labor costs.

The sand mold is hard and dense, and the casting has high dimensional accuracy and smooth surface. Suitable for casting of various metal materials, such as aluminum alloy, copper alloy, zinc alloy, steel, etc.

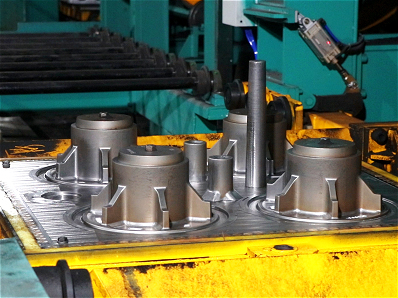

Mold making:

One is to use metal molds, which are more suitable for casting small castings; the other is to use fine sand molds, which are suitable for casting large and complex castings.Preparing the molten material:

The quality of the molten material plays a decisive role in the forming of the casting. Static pressure line casting requires the molten material to have a high degree of purity and uniformity, which can be prepared by smelting, alloying, etc.Charging stage:

This step is to continuously send the prepared mold to the casting machine, and add molten material before the machine starts working. The molten material needs to be heated at a set temperature to avoid problems such as solidification, cooling and crystallization. At the same time, the molten material also needs to be stirred evenly to ensure the chemical uniformity of the casting.Pre-pressing stage:

Pre-pressing is an essential step in the casting process. It can ensure high surface finish and stable performance of castings. After pre-pressing, the surface of the casting needs to be cut off and trimmed.Static pressure stage:

Static pressure is the core part of static pressure line casting, which directly determines the shape and performance of the casting. Static pressure uses a mechanical device to squeeze the melt in the mold so that it evenly fills the entire mold cavity to ensure that the casting has good mechanical properties, chemical composition and structural uniformity.Pressure-holding stage:

After the static pressing is completed, a certain period of pressure-holding treatment is required to enable the casting to obtain better crystallization and grain boundary clarity, and to improve the structural uniformity of the casting.Demold stage:

Demold refers to the operation of removing the casting from the mold. This operation requires great care to avoid damaging the surface and internal structure of the casting.

| Type |

Size of Sand Mold |

Compaction pressure |

Power |

Sand mold weight |

| TZZJ-550*450 | 550*450 | 0.6 | 24 | 85 |

| TZZJ-600*500 | 600*500 | 0.7 | 28 | 130 |

| TZZJ-650*550 | 650*550 | 0.7 | 28 | 150 |

| TZZJ-710*610 | 710*610 | 0.7 | 36 | 210 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.