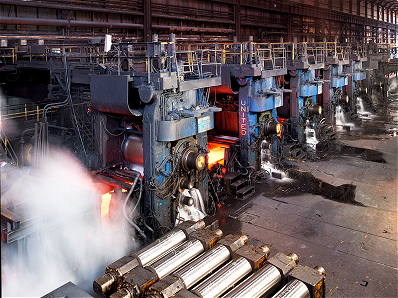

Copper Cold Rolling Mill is an important metal processing equipment and is widely used in metallurgy, machinery, construction and other industries. It processes copper strips into products of required thickness and size by cold rolling.

Copper Cold Rolling Mill is a piece of equipment specially used for cold processing of copper strips. It can prepare high-precision thin film resistors, magnetic materials, flexible circuit boards, high-frequency wires and connectors, and various mechanical parts. This powerful equipment can not only improve the surface quality and mechanical properties of copper strips, but also extend its service life. Therefore, it has been widely used and promoted in many fields.

Feeding and Cutting:

Feed the copper strip into the cold rolling mill and cut it into appropriate length for the next step.

Primary Rolling:

The cut copper strip is subjected to the pressure of the blooming mill roll to cause preliminary deformation. Primary rolling can eliminate the internal stress of the material, improve the plasticity of the material, and prepare for subsequent rolling.

Intermediate Rolling:

After primary rolling, the copper strip passes through the pressure of the intermediate rollers to further adjust the thickness and size. Intermediate rolling generally uses multiple roller tables in series to gradually reduce the gap between the roller tables, so that the thickness of the copper strip can be more carefully controlled.

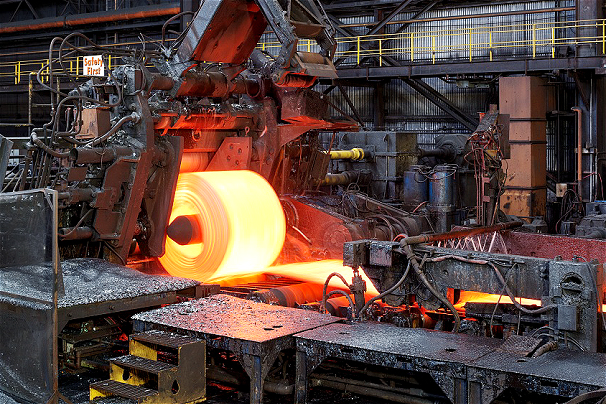

Finishing Rolling:

After intermediate rolling, the copper strip enters the action area of the finishing roll. The finishing roll usually rotates at high speed and uses a large rolling force to deform the copper strip again so that it reaches the required thickness and size.

Discharging:

After finishing rolling, the copper strip is sent out of the cold rolling mill and enters subsequent processes or becomes the final product.

Through the cold rolling process, the surface of the copper strip is smoothed and brightened. This treatment can effectively improve the defects and oxide skin problems on the surface of the copper strip and improve the surface quality of the copper strip.

Products can be customized according to the actual needs of customers.

The Copper Cold Rolling Mill can perform various treatments such as stretching, compression, and bending on the copper strip. These treatments can improve the mechanical properties of the copper strip, increase its strength and toughness, and make it more suitable for use in different fields.

After the copper strip is cold-rolled, its internal grain structure is changed and refined, making it more corrosion-resistant and fatigue-resistant, and extending the service life of the copper strip. After being processed by a copper strip cold rolling mill, the dimensional error of the copper strip can be effectively reduced, making it more in line with customer requirements.

The rolling principle of the copper cold rolling mill is based on the law of metal plastic deformation. During the cold rolling process, the copper strip is squeezed and stretched by the machine's rollers, causing it to undergo plastic deformation after multiple rollings to achieve the required size and shape.

| Type |

Coil Width |

Coil Thickness |

Backup Roll Diameter |

Work roll diameter |

| GXG-750 | 550-650 | 3-0.2 | Ø650 | Ø160 |

| GXG-850 | 650-750 | 3-0.2 | Ø730 | Ø165 |

| GXG-950 | 750-850 | 3-0.2 | Ø800 | Ø175 |

| GXG-1150 | 800-950 | 3.5-0.3 | Ø950 | Ø300 |

| GXG-1450 | 900-1250 | 4-0.3 | Ø1250 | Ø450 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.