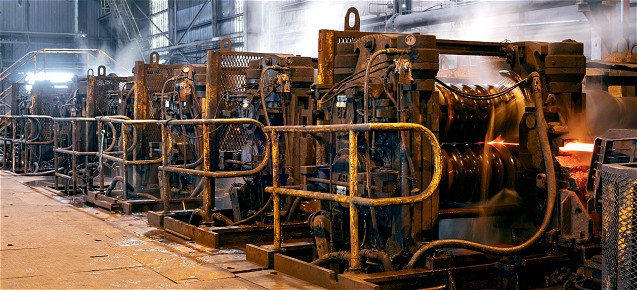

| Equipment list | Smelting furnace, continuous casting machine, heating furnace, rolling mill, cooling bed, collecting and packaging table |

| products | Rebar, Φ 6~8mm wire, Φ 8~40mm steel rebar |

| Billets size | 60*60mm, 70*70mm, 80*80mm, 90*90mm, 100*100mm, 120*120mm, 130*130mm, 150*150mm, 180*180mm, etc. |

| Capacity Range | 1T/H ~150T/H, customized according to clients' requirement |

| Factory area | 1,000m2 to 25000M2 according to different capacity |

| Power volume | 1200kW to 100,000KW |

The ordinary steel bar undergo pre-treatment, such as removing surface rust and impurities. Then the steel bar passed through the forming rolls of the cold-rolled ribbed rebar equipment and are forced through the complex convex and concave shapes on the rolls, creating ribs on the surface of the steel bar. Finally, the processed cold-rolled ribbed steel bars undergo subsequent processing such as shearing to obtain the required specifications and lengths. Ribbed steel bar equipment has been carefully designed and optimized to have strong advantages in mechanical force and metal processing capabilities, and can handle various specifications and types of steel bars to meet the needs of different projects.

Save Time! Get A Detailed Quotation Quickly.