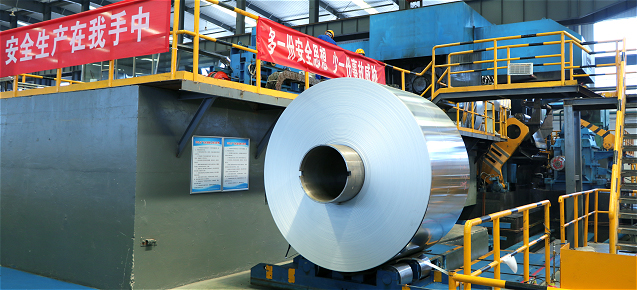

| Equipment list | Gas Melting furnaces, Casters, Cold Rolling Mill, Annealing furnace...Etc. |

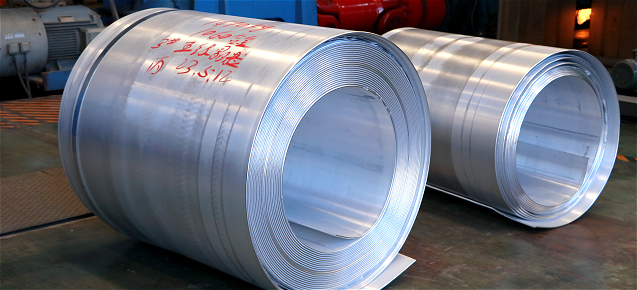

| products | 0.1mm~4mm Aluminum Coils |

| Coil Width | 600mm~2500mm |

| Capacity Range | 3000TPA ~100000TPA |

| Factory area | 1,000m2 to 25000M2 according to different capacity |

| Power volume | 2000KW ~ |

Save Time! Get A Detailed Quotation Quickly.