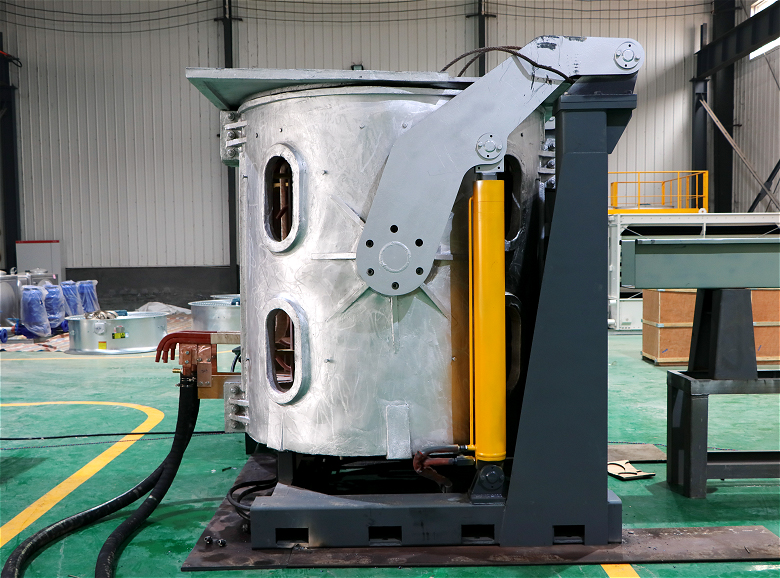

Aluminum Shell Mediate Frequency Furnace is a name for a simple mediate frequency melting furnace. It is a very commonly used melting furnace in the foundry industry. Especially the 500 kg and 1000 kg furnace bodies are the mainstream equipment in the foundry industry. Mainly used for smelting cast iron, stainless steel, alloy steel, non-ferrous metals, heavy metals and precious metals.

Aluminum Shell Induction Furnace usually consists of furnace body, inductor, transformer, capacitor, etc. The furnace body is generally made of aluminum alloy material. The inductor is a key component that generates heat. It is made of copper tubes and placed in the furnace body. It generates eddy currents through electromagnetic induction, heating and melting the metal materials.

The furnace body is made of alloy aluminum sand casting. It has the advantages of high melting efficiency, energy saving, uniform metal composition, less burning loss, fast temperature rise, and easy temperature control and so on. It is suitable for various metal smelting occasions. Low price, easy to repair and easy to observe.

The aluminum shell furnace body adopts a thickened high-quality aluminum alloy shell to ensure the strength of the furnace body; the thick-walled induction coil uses T2 standard copper tube, which can provide more melting energy. The open space between the turns of the induction coil improves the electrical efficiency; the open furnace bottom reduces water vapor, and a cooling ring is designed at the bottom to extend the service life of the furnace lining.

Generally, two furnaces are configured, one for production and the other for backup. Equipped with a reducer tilting mechanism, the reducer bracket is fixed on the base platform. The entire furnace body can be tilted 95 degrees. After pouring out the molten metal, it can be restored to a horizontal position.

The furnace body adopts a thickened high-quality aluminum alloy shell to reduce magnetic leakage while ensuring the strength of the furnace body; the thick-walled induction coils are all made of T2 standard copper tubes, which can provide more melting energy and the open space between the turns of the induction coils improves the electrical efficiency.

Customized design according to the actual needs of customers.

The open furnace bottom reduces water vapor, and a cooling ring is designed at the bottom, which further extends the life of the furnace lining. It has the advantages of high melting efficiency, fast melting speed, energy saving and environmental protection.

It has compact structure, strong overload capacity, low temperature around the furnace, less smoke and dust, good working environment, reliable melting operation, fast melting temperature rise, easy control of furnace temperature, high production efficiency, good heat dissipation performance, low cost and small floor space.

Under the action of the alternating electromagnetic field, eddy currents are generated inside the furnace charge, thereby achieving the effect of heating or melting. The induction coil generates a high-frequency AC magnetic field, and then generates heat in the object through induced current to achieve heating purposes.Under the stirring action of this alternating magnetic field, the composition and temperature of the material in the furnace are relatively uniform. The forging heating temperature can reach 1250°C, and the melting temperature can reach 1650°C.

| Furnace Tonnage T |

PF Voltage |

Power |

Mediate Frequency Voltage |

Pulse |

Power Consumption |

| 0.75 | 3φ380 | 400 | 1600 | 6 | 700 |

| 1 | 3φ380 | 700 | 1600 | 6 | 700 |

| 1.5 | 3φ660 | 1000 | 1600 | 6 | 680 |

| 2 | 6φ800 | 1500 | 2600 | 12 | 630 |

| 3 | 3φ950 | 2000 | 2800 | 6 | 650 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.