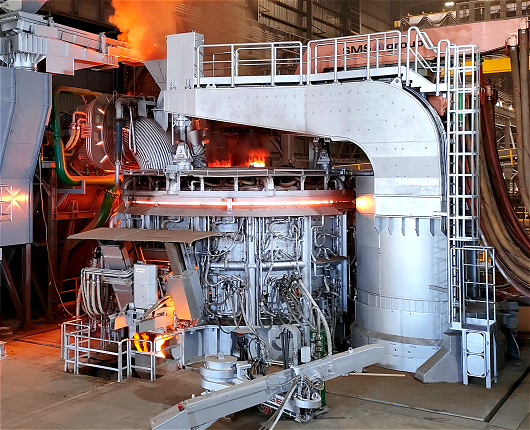

Electric Arc Furnace is an electric furnace that uses high temperatures generated by electrode arcs to smelt ores and metals. When gas discharge forms an arc, the energy is very concentrated, and the temperature in the arc area is above 3000°C. Therefore, compared with other steel-making furnaces, electric arc furnaces have greater process flexibility for melting metals, and can effectively remove sulfur, phosphorus and other impurities. The furnace temperature is easy to control, and the equipment occupies a small area, so it is suitable for the melting of high-quality alloy steel.

Electric Arc Furnace uses electric energy as its main energy source. The electric energy discharges and draws the arc through the graphite electrode and the furnace charge, generating high temperatures as high as 2000℃ to 6000℃. The scrap steel raw materials are melted by arc radiation, temperature convection and heat conduction.

During most of the time when the furnace charge is melted, the high-temperature heat source is surrounded by the furnace charge. The heat loss caused by the high-temperature exhaust gas is relatively small, so the thermal efficiency is higher than that of other steelmaking equipment such as Converters.

Electric heating is easy to control the furnace temperature accurately, and the heating operation can be performed under conditions such as oxidizing atmosphere or reducing atmosphere, normal pressure or vacuum according to process requirements.

Electric Arc Furnace has strong adaptability to the furnace charge. It uses scrap steel as the main raw material, but it can also use solid and liquid iron-containing raw materials such as molten iron, sponge iron, and pig iron blocks.

The atmosphere in the Electric Arc Furnace is controllable, and the operation of adjusting or replacing the slag is relatively simple, and it can finish the complex process of melting, decarburization, dephosphorization, degassing, inclusion removal, temperature control, composition adjustment and others in the same operating system.

The ability to melt solid furnace charge is very strong, and the molten iron is superheated and the chemical composition is adjusted under the condition of being covered with molten slag, so It can avoid the absorption of liquid iron and the oxidation of elements to a certain extent.

Customized design according to the actual needs of customers.

The Electric Arc Furnace has high melting temperature, high production efficiency and short production cycle. At the same time, the metal materials used in electric arc furnaces can be recycled, reducing the consumption of natural resources. In addition, while reducing charge loss, electric arc furnaces can effectively reduce carbon emissions and promote low-carbon production.

The arc discharge in Electric Arc Furnace directly acts on the smelted materials, so the conversion efficiency is high and the energy utilization rate is high. Electric Arc Furnace can also better meet environmental protection requirements during the production process, are more energy-saving and efficient, and have more stable cost control.

After an electric arc is generated between two electrodes in the electric arc furnace by an arc ignition device, the material in the furnace begins to heat up. When the arc combustion is stable, metal materials can be added in the furnace. As the arc continues to exist, the materials in the furnace will gradually melt, and the melted material is called a molten pool. In the molten pool, various impurities can separate from the metal melt. With proper operations, these impurities can be removed from the metal melt, thereby improving the purity of the metal. The slag collected in the molten pool will usually float on the surface of the melt and can be removed through appropriate operations. When the metal reaches the required furnace time and purity requirements, disconnect the power supply and pour out the molten pool smoothly to complete the entire smelting process.

| Furnace Tonnage |

Rated CY |

Inner DIA of furnace shell |

Electrode DIA |

Cooling water consumption |

| HX-5 | 5 | Φ3220 | Φ300 | 80 |

| HX-8 | 8 | Φ3400 | Φ300 | 100 |

| HX-10 | 10 | Φ3500 | Φ350 | 120 |

| HX-15 | 15 | Φ3800 | Φ350 | 150 |

| HX-20 | 20 | Φ4200 | Φ400 | 180 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.