About Induction melting solution

The recycling and reuse of scrap metal can save a lot of money and energy for enterprises and promote the sustainable development of enterprises. However, the intermediate frequency smelting furnace is suitable for the smelting of various metals such as steel, iron, copper, aluminum, etc., and realizes the secondary utilization of scrap metal. Therefore, it has become the preferred smelting equipment for metallurgy, casting, steel and other industries.

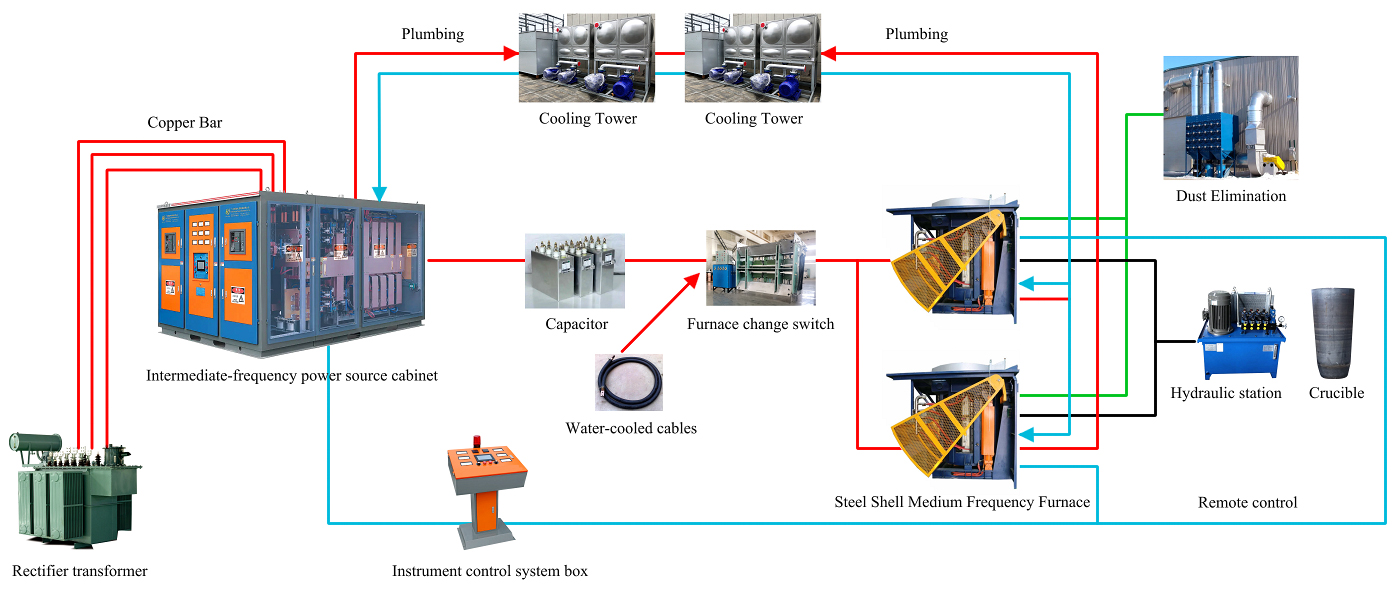

Our company's power supply for the Medium Frequency Furnace adopts high-performance, high-density, large-scale dedicated integrated modules, which makes the trigger circuit fully digital and has the characteristics of good reliability, high accuracy, strong anti-interference ability and fast response speed. The inverter adopts scanning zero-voltage start and has an automatic repeated start circuit. The starting performance is better than the intermediate frequency power supply widely used in the domestic market. The success rate can reach 100%. The frequency following circuit adopts an average sampling scheme to improve the inverter's anti-jamming capability, makes starting more convenient and reliable.