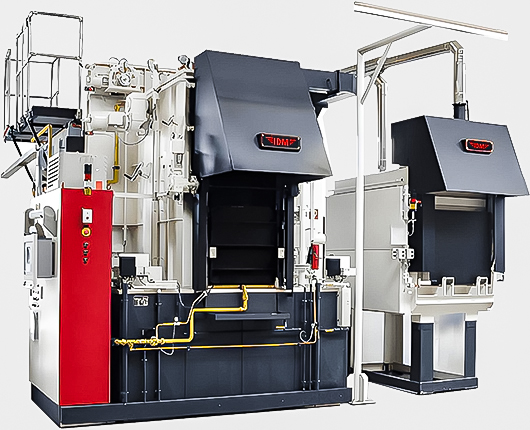

Box-Type Multi-Purpose Furnace is An industrial furnace that integrates carburizing, quenching, tempering, and cleaning processes into one system.

Configuration of the Box-Type Multi-Purpose Furnace:

It consists of a box-type carburizing and quenching multi-purpose furnace, transfer car, vacuum or warm-water cleaning machine, tempering furnace, preparation station, finishing station, and a distributed control system with human-machine interface.

Application Scope:

The box-type carburizing multi-purpose furnace is an industrial furnace with a box structure that integrates multiple heat treatment processes, including carburizing, quenching, tempering, and cleaning.

The cylindrical chamber design optimizes the thermal radiation and hydrodynamic fields, significantly improving temperature uniformity and atmosphere flow consistency to ensure even heat treatment product quality.

Equipped with Germany's top PE brand process controller and zirconia oxygen probe, it enables real-time, precise control for flawless process execution and guaranteed, reliable heat treatment results.

A unique quench oil tank flow guide device, coupled with automatic oil temperature control and infinitely variable agitation speed, effectively minimizes product deformation while improving hardenability and hardness uniformity.

The equipment primarily employs pneumatic actuation for its straightforward, practical, and reliable design.

The three-position vestibule design allows for atmosphere purging and loading of the next charge simultaneously with quenching or slow cooling, minimizing furnace idle time and boosting production efficiency.

The latest distributed control system, featuring a versatile HMI with computer control and dedicated management software, ensures highly controllable production line operation and user-friendly interaction.

Equipped with Germany's top-tier PE brand heat treatment process controllers and zirconia oxygen probes, the system enables real-time, precise online control of the heat treatment equipment. This ensures flawless process execution and reliably stable, high-quality heat treatment results.

Customized design according to the actual requirement of customers.

The equipment is designed with advanced and rational composition, ensuring excellent stability and low operating costs. It utilizes world-renowned brand components, guaranteeing reliable durability and minimizing electricity, gas consumption, and maintenance expenses.

All product process operations are controlled by PLC, achieving a high level of automation. The system monitors products in real-time across different process stages, and all process parameters can be configured with limit alarms, notifications, and automated handling functions.

The box-type multi-purpose furnace operates based on controlled atmosphere heat treatment technology. By precisely regulating three key parameters—temperature, atmosphere composition, and time—within a sealed chamber, it enables both chemical heat treatment (such as carburizing and nitriding) and physical heat treatment (such as quenching and tempering) of workpieces under protective or reactive atmospheres.

Stage 1: Pre-treatment and Loading

Stage 2: Purging and Atmosphere Establishment

Stage 3: Heating and Diffusion

Stage 4: Quenching/Cooling Treatment

Stage 5: Post-treatment and Cleaning

| Type |

Dimensions |

Work Chamber Size |

Pit Depth |

Loading Capacity |

Furnace Capacity(KVA) |

Operating Temperature |

Weight |

| IDM-BMF-1 | 3200*2200*4630 | 910*610*610 | 300 | 500 | 120/72 | 750-1000 | 10000 |

| IDM-BMF-2 | 4090*2430*4520 | 1220*760*610 | 750 | 1000 | 188/126 | 750-1000 | 12000 |

| IDM-BMF-3 | 4090*2430*5070 | 1220*760*760 | 750 | 1000 | 202/138 | 750-1000 | 12500 |

| IDM-BMF-4 | 4040*2930*5320 | 1220*910*760 | 750 | 1200 | 202/138 | 750-1000 | 14000 |

| IDM-BMF-5 | 4040*2930*5800 | 1220*910*910 | 750 | 1500 | 228/150 | 750-1000 | 15500 |

| IDM-BMF-6 | 4695*2930*4870 | 1520*1220*610 | 500 | 1200-2500 | 260/171 | 750-1000 | 17000 |

| IDM-BMF-7 | 4695*2930*5320 | 1520*1220*760 | 500 | 1500-2500 | 300/184 | 750-1000 | 17000 |

| IDM-BMF-8 | 4695*2930*5895 | 1520*1220*910 | 800 | 1500-2500 | 324/240 | 750-1000 | 17500 |

| IDM-BMF-9 | 5890*3230*6425 | 1800*1500*1200 | 2050 | 2000-5000 | 477/315 | 750-1000 | 30000 |

*The output will vary according to different materials, feed particle size and other factors

Save Time! Get A Detailed Quotation Quickly.