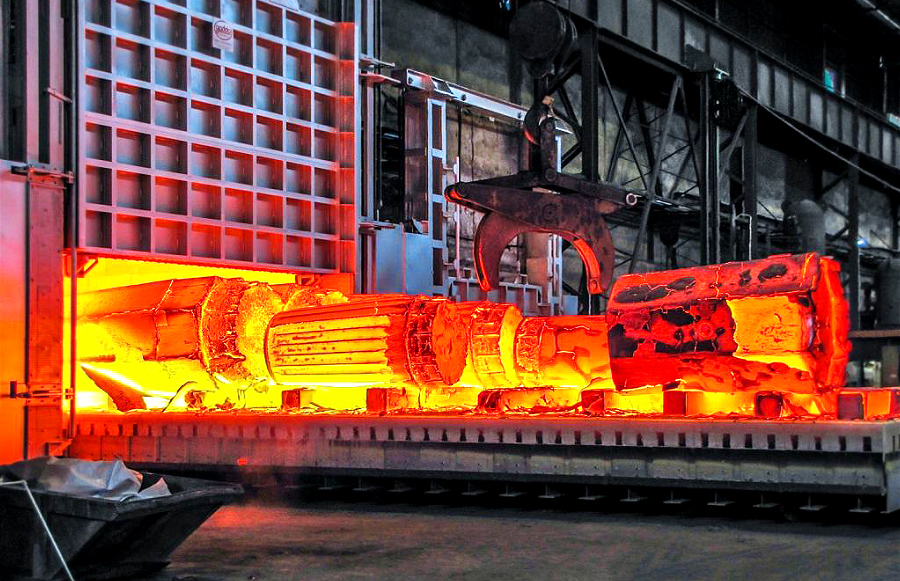

An operation in which steel is heated above a critical point or recrystallization temperature for a period of time and then slowly cooled to a cooling rate less than that in still air is called annealing. The purpose of annealing is:

(1) Reduce hardness, improve shaping and toughness for cutting or press working;

(2) Reducing residual stress;

(3) Eliminate structural defects in steel, such as coarse grains and uneven composition.

It can be seen that in most cases, annealing is to eliminate and improve the structural defects and internal stress left in the previous process, and to prepare for the organization and performance of the subsequent process.

Annealing can be classified into diffusion annealing, complete annealing, incomplete annealing, spheroidizing annealing, recrystallization annealing depending on the heating temperature.

After the steel is austenitized and rapidly cooled at a rate greater than the critical cooling rate, the supercooled austenite can be transformed into martensite. This operation is called quenching.

(1) Good comprehensive mechanical properties obtained by quenching and subsequent tempering;

(2) changing some of the physical and chemical properties of steel (such as improving magnetic properties);

(3) Prepare for the next heat treatment.

In the steel rolling production, the martensite steel can be quenched by itself in air-cooled state to obtain quenched structure.

The microstructure stress of the hardened steel is so large that quenching cracks are generated when the surface is ground and cleaned, and the structural stress caused by quenching must be eliminated by tempering.

The quenching at the end of the heavy rail is heated by high frequency induction and then water quenched. This method is called high frequency quenching.

Save Time! Get A Detailed Quotation Quickly.